In many cases the type of protective system needed is well known and simple to use. At other times employers will undertake the more complex process of designing a protective system. Designing a protective system requires consideration of many factors, including: soil classification, depth of cut, water content of soil, weather and climate, and other operations in the vicinity. Employers are free to choose the most practical design that will provide the necessary protections. Any system used must meet the required performance criteria.

The Excavation standards describe various methods and approaches that can be used to design protective systems. Examples of protective systems that can be used to comply with the Excavation standards include:

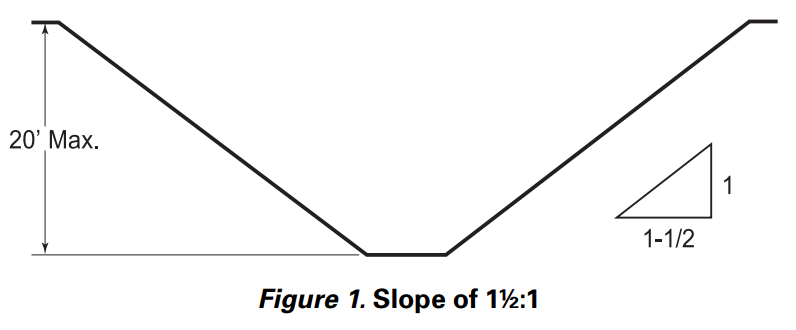

Sloping the sides of the excavation to an angle not steeper than 1½:1 (for every foot of depth, the trench must be excavated back 1½ feet). A slope of this gradation is safe for any type of soil.

Designing a sloping and benching system in accord with tabulated data, such as tables and charts, approved by a registered professional engineer. This data must be in writing and must include enough explanatory information (including the criteria for selecting a system and the limits on the use of the data) for the user to be able to select an appropriate protective system. At least one copy of the data, which identifies the registered professional engineer who approved it, must be kept at the worksite during construction of the protective system. After the system is completed, the data may be stored away from the jobsite, but a copy must be provided upon request to an OSHA compliance officer.

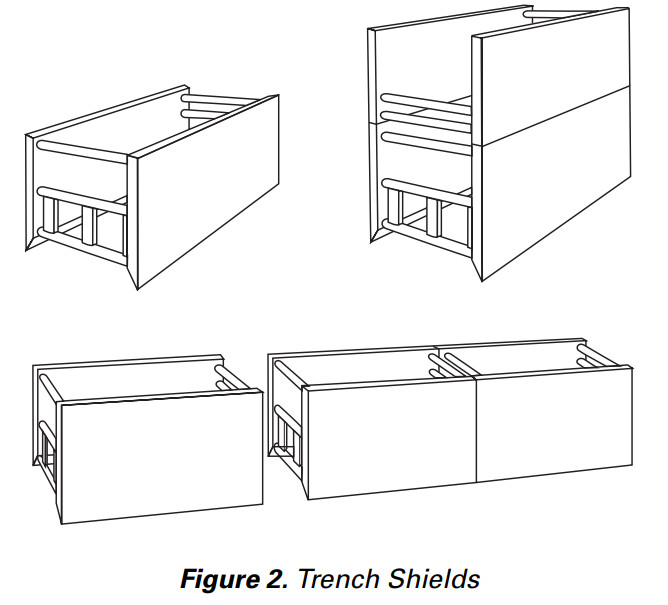

Using a trench box or shield approved by a registered professional engineer or designed in accord with tabulated data approved by a registered professional engineer.

The Excavation standards do not require a protective system when an excavation is made entirely in stable rock or when an excavation is less than 5 feet (1.52 meters) deep and a competent person has examined the ground and found no indication of a potential cave-in.

At Ron Meyer & Associate Excavating, Inc, we’ve been providing underground and commercial construction to private and commercial businesses for 39 years. As the general contractor or subcontractor, our experienced foremen, equipment operators, pipe layers, truck drivers and well-maintained equipment fleet make us an undeniable choice for your excavating services. Let’s talk about your project!

Sources:

- https://www.osha.gov/Publications/osha2226.pdf

As 45 years of experience as an underground/site contactor and a third generation contractor, Ron takes time to go through each individual project with the supervisor and is responsible for all scheduling and equipment logistics. He’s also involved in all troubleshooting for projects.